Castresin-Type Busbar Trunking System (CTBTS) is an electrical distribution system consisting of copper or aluminum conductors enclosed within an epoxy resin mixture. This design provides enhanced insulation, longevity, and resistance to adverse environmental conditions. This design is especially well-suited for demanding IP68 applications found in power plants, oil & gas sectors, and severely hostile regions and terrain.

DeltaBar is the first single-extracted aluminum single-body cast resin system manufacturer in the universe, and it’s truly an IP68 busway system, including single-run feeder elements from 800A to 3200A, multiple feeder components from 4000A above, and plug-in tap-off units (IP66 rated) up to 1250A. Completely type-tested, the first and only Cast Resin-Type producer in the Middle East, founded in 2006, is the only company that guarantees its product requires no maintenance for the rest of its life once installed in its right method, complying with manufacturer standards.

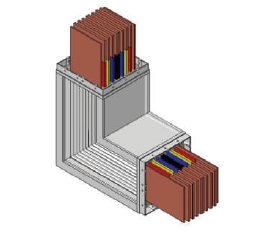

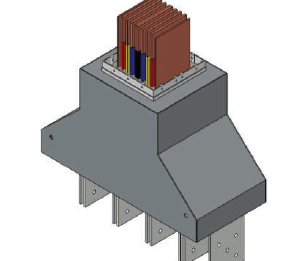

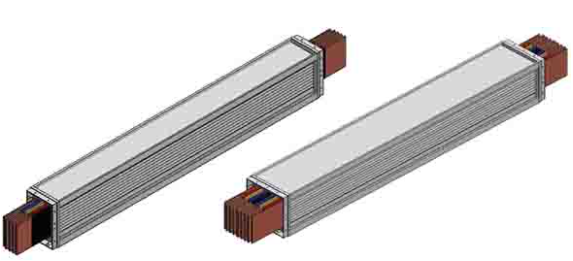

This is possible thanks to its fully encapsulated design consisting of a unique single-piece extruded aluminum body with fins that play an integral part in the dissipation of heat, allowing the combination of each conductor spaced evenly within the duct and mechanically stacked permanently by the CAST-RESIN, robust material properties, which ensure long-term reliability.

Epoxy Resin Encapsulation: The conductors are fully encased in epoxy resin along with a single-piece extruded aluminum body, which offers superior electrical insulation and defense against environmental elements like dust, moisture, and corrosive substances. The exposed parts no longer require routine cleaning or inspection.

Corrosion Resistance: Even in humid or coastal areas, the resin eliminates the chance of corrosion by preventing any contact with air or water, in contrast to traditional systems with exposed conductors.

Mechanical Strength: The resin’s great resistance to impacts, vibrations, and mechanical shocks ensures endurance over time without the need for reinforcements or adjustments.

Thermal Stability: With our superior metal enclosure consisting of fins, heat dissipation takes place, keeping the elements at their nominal temperature. The capacity to withstand high temperatures increases and guarantees steady operation free from overheating or deterioration.

Improved Safety: Electrical shocks and short circuits are avoided by the fully insulated architecture.

Maintenance-Free: Regular inspections and repairs are not necessary due to the strong resin coating and its additional metal enclosure body.

Longevity: Even under harsh circumstances, the system’s resilience guarantees a lengthy service life.

Resistance to Environmental Factors: Works well in places where people are exposed to chemicals, moisture, and dust, even in ice.

Industrial Facilities: Particularly in settings like chemical facilities that have high humidity or caustic atmospheres.

Marine and Offshore: It does not corrode in seawater; it is used on ships and oil platforms.

Substations and tunnels: Perfect for areas with restricted ventilation and fire safety regulations.

Renewable Energy Plants: They can tolerate external exposure, and they are appropriate for wind and sun farms.

Oil & Gas Sectors: Due to their reliable and robust solution for uninterrupted, effective power transmission.

Airports: To distribute and transmit high-voltage power without any disruption.