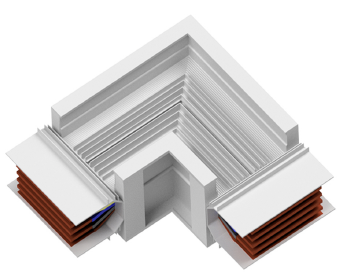

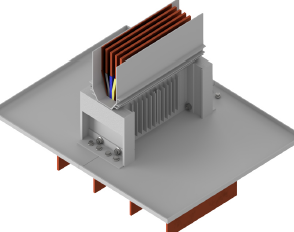

Busbar trunking system (BTS) is an electrical distribution system consisting of copper or aluminum conductors enclosed within a protective housing. These systems are used to distribute electrical power within a building or industrial facility efficiently. Busbar trunking systems offer a compact, flexible, and modular solution for distributing power compared to traditional cable systems.

DeltaBar, being the first and only Bus Duct manufacturer in the Middle East, is proficient in a variety of low- and high-voltage busducts. DeltaBar is committed to providing clients with reliable and state-of-the-art power transmission solutions. We specialize in the design, R&D, manufacture, and installation of a variety of high and low-voltage busducts. Our high-voltage and low-voltage Busduct systems can exceed the satisfaction & requirements of various projects, whether they are in commercial, public, industrial, or government sectors. DeltaBar guarantees that our solutions not only satisfy international standards but also operate dependably in a variety of complicated conditions thanks to our cutting-edge technology.

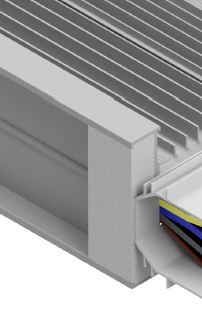

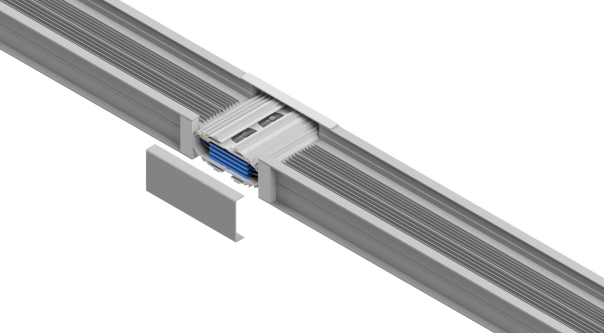

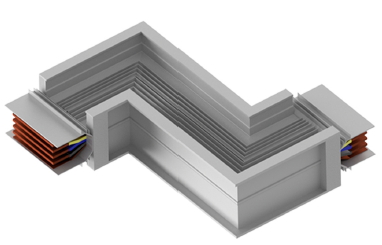

After rigorous and extensive R&D, we developed the first and only busbar trunking system with fins for our product at its core areas, which facilitate airflow and are necessary for efficient cooling, keeping our bus duct trunking system at its nominal temperature that helps to maintain its longevity, making it stand out superiorly from any other brands globally.

- Conductors: Made of copper or aluminum, these carry the electrical current.

- Enclosure: Protects against environmental factors, such as dust, moisture, or mechanical damage.

- Insulation: Ensures safety by preventing electrical faults and leakage.

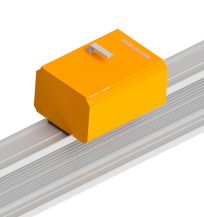

- Tap-Off Units: Allow connections to various loads along the length of the system.

- Joints and Supports: Enable secure mechanical and electrical connections and provide support for the system.

Compact Design: Requires less space compared to traditional cabling systems.

Modular and Flexible: Can be easily extended, modified, or relocated as the facility’s needs evolve.

Reduced Installation Time: Prefabricated components simplify installation.

High Efficiency: Minimizes energy losses due to lower resistance compared to cables.

Enhanced Safety: Offers better fire resistance and reduces the risk of electrical faults.

Load Distribution: Tap-off points make it easier to distribute power to specific areas or equipment.

Commercial Buildings: Efficient power distribution to different floors or zones.

Industrial Facilities: Powering heavy machinery or production lines.

Data Centers: To ensure reliable and scalable power distribution.

Shopping Malls: High-density and flexible power supply.

Airports: For uninterrupted, effective power transmission.

Transportation: Power supply and lighting systems in transit hubs like subways and train stations.

Energy Industry: The Busbar trunking system is used in power plants and substations to distribute and transmit high-voltage power.

Manufacturing Plant: Large machinery and equipment are connected using a Busbar trunking system in factories and manufacturing facilities to guarantee a steady power supply.

Shipyard and Marine Applications: Compared to an analogous cable installation, the compact form saves space when transmitting large currents, both AC and DC.

Lighting Busbars: Designed for lighting circuits.

Low Power Busbars: For power distribution to smaller equipment.

Medium/High Power Busbars: For high current and power-intensive applications.

Plug-In Busbars: Allow easy connection of devices through plug-in units.